- Home

- Products

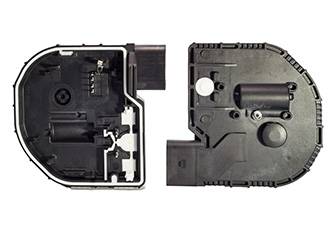

Our offer to you: The development of a customised manufacturing process that combines plastic injection moulding technology with stamping and automation technology. The result for you: High-quality plastic and metal-plastic components for your high-tech products.

Hybrid injection moulding technology allows the advantages of both materials to be optimally combined.

Injection moulding in the multi-component process produces components from several plastics, each with their own material-specific properties.

These serve as core components for heavy-duty electric motors and drives that are used in large quantities in numerous industries.

A high degree of complexity and functional diversity can be achieved by embedding several inserts made of different materials.

Injection moulding of precisely fitting plastic components is carried out with a high degree of automation and the greatest precision. These are used as elements in complex assemblies, among other things.

These are individually assembled cables that are optimal for special applications, such as in sensors.